The Future of Construction: How Steel Fabricators are Shaping It

- FabMFG.net

- May 24, 2024

- 7 min read

Introduction to Steel Fabrication in the Construction Industry

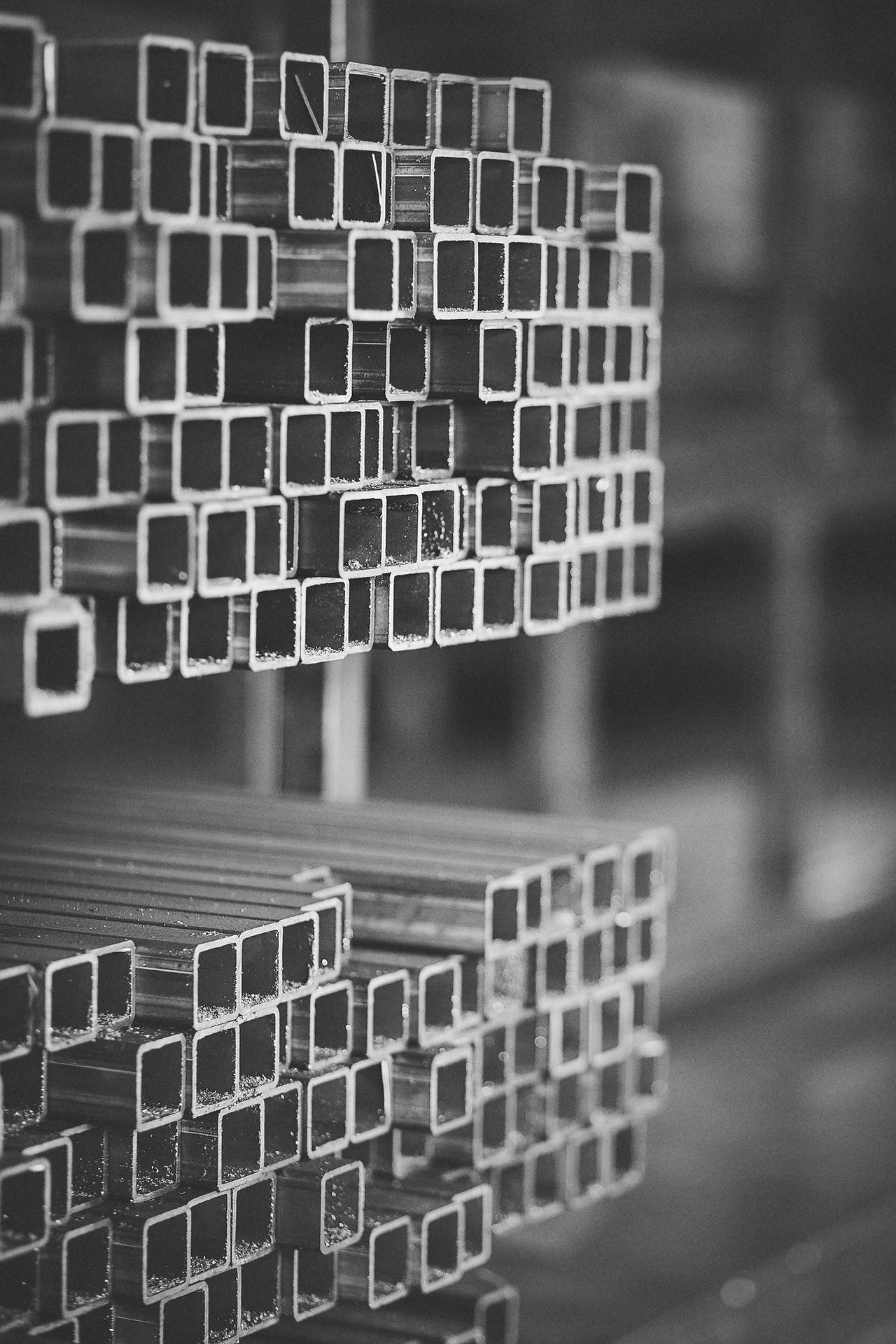

Steel fabrication is the backbone of modern construction. It's the process of cutting, bending, and assembling steel to create structures. Without it, the skyscrapers that kiss the sky and the bridges that span vast waters wouldn't be possible. Here's the deal: steel is strong, durable, and versatile. This makes it a go-to material for builders aiming to bring bold designs to life. Fabricators are the unsung heroes, turning blueprints into real, towering structures. They work with architects and engineers, making sure that each beam and bolt is up to the task of holding up against not just the weight, but also the wrath of nature. What's more, innovation in steel fabrication means we're building faster, safer, and more creatively than ever before. In this section, you've just stepped into the world where steel becomes the skeleton of our modern marvels. Let's dive deeper into how this industry is not just part of construction but is shaping its very future.

The Role of Steel Fabricators in Modern Construction

Steel fabricators play a crucial part in modern construction's backbone, shaping the future with their expertise and innovation. Here's how: they take raw steel and turn it into the stuff buildings and infrastructure are made of. Beams, frames, and even intricate parts of buildings that we often overlook. Think of any modern skyscraper or bridge—the odds are, steel fabricators had their hands on it. Their role goes beyond just cutting and welding steel. They bring architects' visions to life, ensuring structures not only stand tall but are safe and sustainable. With technology, these fabricators are pushing boundaries, using advanced machinery and software to create more with less, ensuring precision that was unthinkable just a few years back. Their work supports green building practices, making it possible to design structures that are not only stronger but also more energy-efficient. In simple terms, without steel fabricators, the futuristic skylines we dream of would remain just that - dreams. They're the unsung heroes of construction, molding the future of our cities one beam at a time.

Innovations in Steel Fabrication Techniques

Steel fabrication is stepping into the future with some game-changing innovations. These aren't just fancy gadgets and gizmos but real, practical changes that are making buildings stronger, construction times faster, and designs more flexible. 3D printing is a big player here, letting builders create complex parts easily and with less waste. Imagine printing a steel beam that's ready to go, tailored exactly to the spot it needs to fit. Then there's automated welding – robots that can work quicker and often more accurately than humans. This means steel structures can be put together faster and with fewer mistakes. And let's not forget laser cutting. This technology allows for incredibly precise cuts, meaning parts fit together perfectly, making buildings even safer. These innovations are more than just improvements; they're transforming how we think about constructing the spaces we live and work in.

How Steel Prefabrication is Revolutionizing Building Processes

Steel prefabrication is changing the game in construction, making building faster, more efficient, and often cheaper. Instead of the old way of cutting, shaping, and assembling steel on the construction site, prefabrication happens in a factory. This means big pieces of a building are made ready-to-install before they even reach the site. It's like having a building kit - precise, quicker to put together, and less waste hanging around. This method is not just speeding things up but also cutting down on costs. Since everything is measured and cut in a controlled environment, there's less room for error, saving money on materials and labor. Plus, working conditions are better in a factory than at a windy, open construction site, making it safer for workers. With the world moving fast, steel prefabrication is one smart way construction is keeping up, offering a greener, cleaner, and more efficient path to building the future.

The Environmental Impact of Steel Fabrication

Steel fabricators play a critical role in shaping the future of construction, but it's important to talk about the environmental side of things too. The process of making and shaping steel for construction projects isn't without its impact on our planet. First off, producing steel requires a lot of energy and resources, including water and coal. This can lead to significant carbon dioxide emissions, a big player in climate change. However, it's not all doom and gloom. The steel industry has been making strides toward greener practices. A lot of the steel we use today is recycled. In fact, steel is one of the most recycled materials on the planet. Recycling steel uses less energy and produces fewer carbon emissions compared to creating new steel from raw materials. Plus, modern techniques in steel fabrication are getting more efficient, cutting down on waste and further reducing environmental impact. So, while steel fabrication comes with its share of environmental challenges, ongoing efforts and advancements are helping to mitigate these issues, contributing to a more sustainable future in construction.

Economic Benefits Brought by Advanced Steel Fabrication

Advanced steel fabrication isn't just about building stronger structures; it's a game-changer for the economy too. First off, steel is everywhere. From the skyscrapers defining our city skylines to the bridges connecting us, steel's role is undeniable. But how exactly does advanced steel fabrication pump money into the economy? Well, for starters, it has made construction projects faster and more cost-effective. Modern fabrication techniques mean steel components are prepared and ready to go, cutting down on-site construction time significantly. This efficiency isn't just good for meeting deadlines; it's excellent for the budget too.

Moreover, the precision of advanced fabrication reduces waste. When components fit perfectly the first time, you're not throwing away materials and money. This precision saves tons of resources over time, which is a win for both project budgets and the planet. And let's not forget the jobs. Advanced steel fabrication requires skilled workers — from the people who design and plan to those who operate the machinery and install the components. As the steel industry embraces more sophisticated fabrication techniques, the demand for these skilled professionals grows. These well-paying jobs contribute to economic growth, supporting families and communities.

So, when we talk about the economic benefits brought by advanced steel fabrication, we're highlighting a chain reaction of positive impacts. More efficient construction projects lead to cost savings and reduced waste, while the growing need for skilled workers boosts employment and supports local economies. It's a solid win-win scenario for the construction industry and beyond.

Steel Fabrication and Its Contribution to Sustainable Construction

Steel fabrication is playing a critical role in pushing construction towards sustainability. This method involves bending, cutting, and assembling steel to create structures. It's not just about building though; it's about doing so in a way that benefits our planet. Here's the deal – steel is one of the most sustainable materials we've got because it's almost endlessly recyclable. Once made, steel can be recycled over and over without losing its strength or quality. This is a big deal in an industry that's constantly looking for ways to reduce waste and environmental impact.

Furthermore, thanks to advances in technology, steel fabricators are now able to design and produce elements with maximum efficiency, meaning less waste during the production process and less energy used. This is crucial for the health of our environment and for pushing the construction industry towards a greener future. What's more, steel's durability means structures last longer, reducing the need for frequent rebuilds or repairs which also conserves resources.

In a nutshell, by using steel, builders are not only opting for a material that meets high standards of durability and flexibility, but they are also making a choice that supports the health of our planet. Steel fabrication is more than just a building technique; it's a pathway to more sustainable construction practices.

Emerging Technologies in Steel Fabrication

Tech in steel fabrication is changing the game. Now, we've got things like 3D printing metal parts and computer models that help plan and track the whole building process. What's cool is that these techs make making things with steel faster, less costly, and a lot more precise. For instance, 3D printing is not just talk; it's already being used to make complex parts that would be super tough to shape using old-school methods. Then, there's automation – robots and machines that can do the heavy lifting and repetitive tasks, cutting down on mistakes and speeding things up. And don't get me started on virtual reality (VR) and augmented reality (AR). These aren't just for games; they're used to visualize projects in real-time, making it easier to catch problems before they turn into expensive mistakes. To sum it up, these tech advancements are pushing steel fabrication into the future, making it possible to build stronger, more innovative structures while saving time and money.

Case Studies: Successful Projects by Steel Fabricators

Steel fabricators have left their mark on the skyline of every major city, and there's no sign of slowing down. Take the example of the iconic One World Trade Center in New York. This marvel wouldn't stand without the ingenuity and precision of steel fabricators. It uses 45,000 tons of structural steel to achieve its towering presence, showing how critical steel is for modern construction. Then there's the Shanghai Tower in China. It's not just another skyscraper; it's a testament to what happens when steel fabrication meets ambitious design. Housing the world's second-fastest elevator, it relies on a unique steel exoskeleton to reach its impressive height while remaining flexible in high winds. These success stories illustrate a clear trend: the future of construction leans heavily on the advancements and capabilities of steel fabricators. They're not just building structures; they're redefining our urban environments with each project completed.

Future Trends: What's Next for Steel Fabricators in Construction

Steel fabricators are central to the construction industry's evolution, pushing the boundaries of what buildings look like and how they're built. Here are a few trends shaping their future. Sustainability is big. Steel is already one of the most recycled materials on the planet. Fabricators are pushing this further by prioritizing not just the recyclability of steel but also how steel is produced, aiming for lower carbon footprints. Next, there's technology integration. From 3D printing to advanced robotics, technology is making fabrication quicker, more precise, and less wasteful. This includes using software for better project planning and management, ensuring steel is used efficiently. Customization is on the rise too. The days of one-size-fits-all are disappearing. Fabricators are now offering more options for customized steel shapes and sizes, allowing for unique architectural designs and pushing innovation in construction techniques. Lastly, collaboration between fabricators and other construction professionals is becoming more important. As projects become more complex, the need for early and effective collaboration increases. This helps in avoiding costly mistakes and ensures that projects are completed on time and within budget. So, the future for steel fabricators in construction? It's about being greener, more efficient, highly customized, and collaborative. With these trends, they're not just shaping steel; they're shaping the future of our built environment.

Comments