Exploring the Benefits of Advanced Steel Bending Methods

- FabMFG.net

- May 18, 2024

- 5 min read

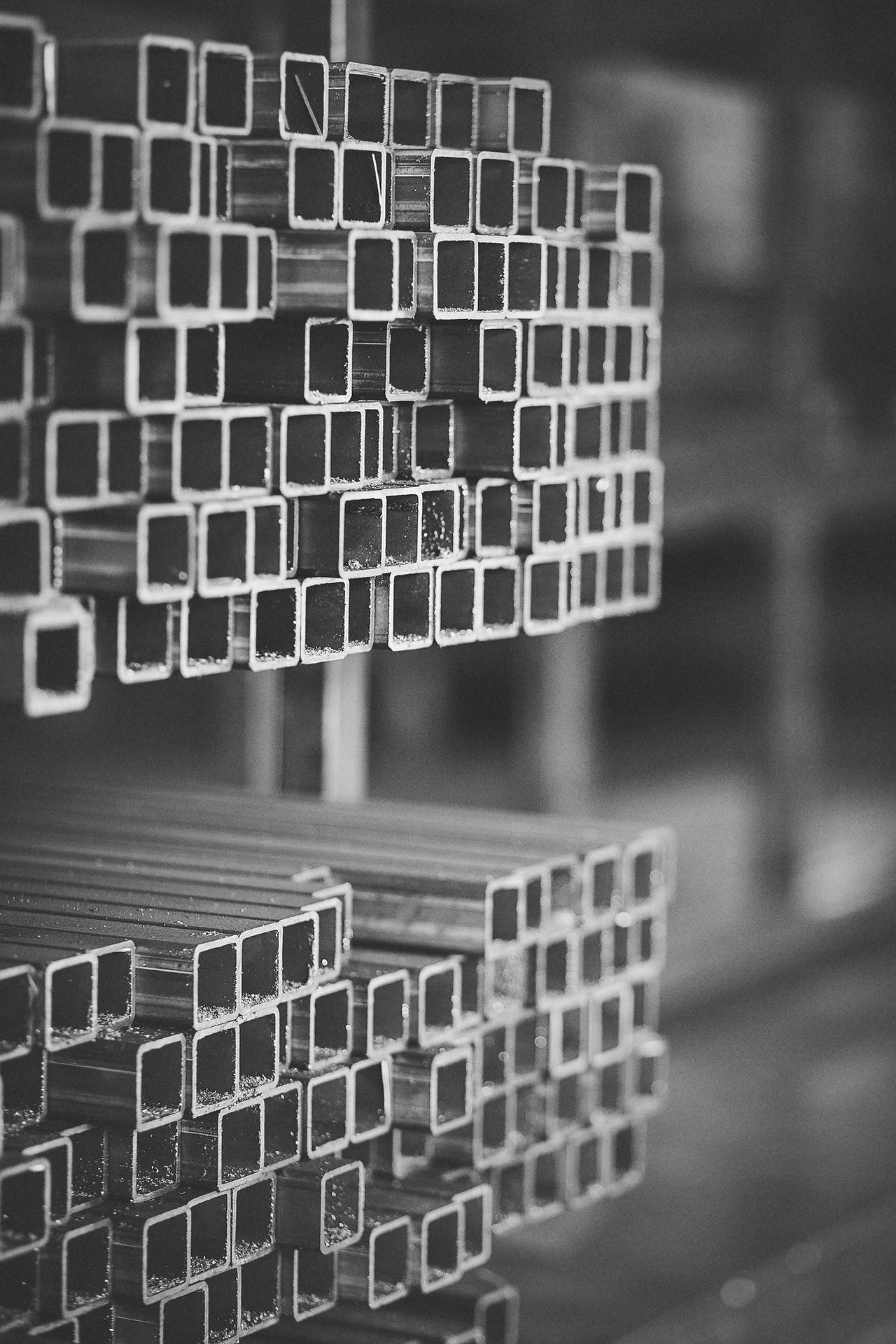

Introduction to Steel Bending: What It Is and Why It Matters

Steel bending is simply shaping steel into desired angles or forms. It's not just bending; it's an art and a science that plays a crucial role in construction and manufacturing. When you bend steel correctly, it can take on new shapes without breaking or losing strength. This technique is fundamental in creating everything from the skeleton of skyscrapers to intricate parts in machinery. Why does it matter? Because without it, our cities' skylines and the machines we depend on daily wouldn’t exist as they do. Advanced bending methods have pushed the boundaries, allowing for more complex and efficient structures to be built. Understanding steel bending is the first step in appreciating these advances in construction and engineering.

The Evolution of Steel Bending Techniques

Steel bending techniques have come a long way. Back in the day, blacksmiths would manually hammer steel over anvils to get the desired shape. It was effective but took a lot of time and muscle. Fast forward to today, and the process has evolved significantly. Now, we have machines and advanced technologies that can bend steel with precision and efficiency. These modern methods include press brake bending, roll bending, and induction bending, among others. Press brake bending uses a press machine to bend steel into shapes and angles with high accuracy. Roll bending involves passing steel through rollers to achieve curves. Induction bending uses heat to make steel malleable for bending. Each method has its own set of advantages, such as improved precision, the ability to bend thick materials, and achieving complex shapes with fewer efforts. This evolution in steel bending techniques not only speeds up the manufacturing process but also opens up new possibilities in construction and design.

Overview of Advanced Steel Bending Methods

Today's advanced steel bending methods are not just about brute force. They combine the precision of technology with the strength of steel, giving us ways to shape steel that were hard to imagine before. We're talking about techniques like induction bending, rotary draw bending, and roll bending. Each comes with its own advantages, tailored to different needs. Induction bending uses heat to make the steel more pliable, perfect for tight curves. Rotary draw bending is all about precision, ideal for creating consistent, tight radius bends. Roll bending, on the other hand, is great for larger curves, where a series of rollers push and bend the steel. These methods expand our capabilities, making it possible to tackle complex projects and achieve results that match our vision, down to the last bend.

Increased Precision with Advanced Steel Bending

Advanced steel bending techniques have made a big leap in how we shape steel for construction and manufacturing. These modern methods offer much higher precision than older ways. Think less guessing, more accuracy. This precision means parts fit better, projects look cleaner, and structures are stronger. With advanced bending, you can bend steel into complex shapes and tight angles without losing strength or quality. This opens up new possibilities for design and functionality. In short, advanced steel bending lets us do more with steel, easier and with less waste. It's all about making things better and more accurate, from bridges to buildings to everyday products.

Enhanced Strength and Durability in Bent Steel

When steel is bent using advanced methods, it doesn’t just take on a new shape; it turns into a tougher version of itself. Think of it like working out. Just as muscles grow stronger with exercise, steel becomes stronger at the bends when processed with precision techniques. This is because these methods improve the steel's grain structure, making it more resistant to wear and tear. That means structures made from this steel can handle heavy loads and harsh conditions without bending out of shape or breaking. Whether it's a bridge, a building frame, or a piece of machinery, using steel bent with advanced techniques ensures it'll last longer and stand up to whatever comes its way. In simple terms, this steel won't give up easily, making whatever it's used in sturdier and more reliable.

The Aesthetic Advantages of Modern Steel Bending Techniques

Modern steel bending techniques are not just about strength and durability; they bring an unmatched level of aesthetic appeal to the table. These advanced methods allow for more creative designs and smoother curves. This means architects and designers can now dream up structures that were once thought impossible. Buildings can have flowing, organic shapes, and bridges can arc across the sky with a grace that old, rigid methods could never achieve. With these techniques, the potential for innovative and visually striking projects is limitless. The smooth bends and precise angles created with these methods can transform a simple structure into a work of art. Whether it's creating a sleek modern look or invoking the fluid lines of nature, advanced steel bending brings an aesthetic advantage that sets projects apart in today's design landscape.

Cost-Effectiveness of Using Advanced Steel Bending

Advanced steel bending technologies save money in the long run. Traditional bending methods can be cheaper upfront but cost more due to waste, extra labor, and the time needed to finish a project. Advanced methods, like CNC bending, are precise, leading to less waste and fewer mistakes. This precision means projects complete faster and use less material, saving costs on both fronts. Additionally, high-quality bends reduce the need for repairs or adjustments down the line, further slashing expenses. So, while the initial investment in advanced steel bending might seem high, the overall savings are significant, making it a cost-effective choice for businesses.

The Environmental Impact of Improved Steel Bending Methods

Using advanced steel bending methods has a green side, and it's worth talking about. These updated techniques waste less material. In the old days, more steel got tossed because it couldn't be bent right. Now, machines do it with precision, using exactly what's needed and no more. This cuts down on waste big time. Also, modern methods need less energy. Less energy means fewer emissions, which is better for our planet. It's like this - better technology in steel bending not only shapes metal more efficiently but also helps keep the Earth cleaner. Every bit of steel shaped right, with minimal waste and lower energy use, is a step towards a healthier environment.

Applications and Examples of Advanced Steel Bending in Industry

Advanced steel bending methods have revolutionized many industries by offering precision, efficiency, and durability. This technique is crucial in sectors like construction, automotive manufacturing, and aerospace. For instance, in construction, advanced bending is used to create strong frameworks for buildings and bridges, ensuring they can withstand natural disasters and heavy loads. Automotive industries rely on this method to produce parts with complex shapes and angles, enhancing the aerodynamics and safety of vehicles. In the aerospace sector, precision bending is vital for fabricating components of aircraft that must meet exact specifications for performance and safety. Furthermore, the furniture and art installations benefit from steel bending, allowing for creative designs that are both aesthetically pleasing and structurally sound. These examples show how this technology supports innovation across different fields, making products safer, more reliable, and efficient.

Concluding Thoughts on the Future of Steel Bending Technology

As we look toward the future of steel bending technology, it's clear that the industry is poised for some exciting advancements. These new methods, from precision laser cutting to advanced automated systems, promise not only to enhance how we work with steel but also to revolutionize the construction and manufacturing worlds. The key takeaway? We're looking at faster, more precise steel bending that can cater to complex shapes and designs with ease. This means buildings can be stronger, machines more efficient, and overall production costs might see a significant reduction. The future is bright, and as technology advances, so too will our ability to push the boundaries of what’s possible with steel. Let's embrace these changes, ready to adapt and learn, always pushing forward to the next big thing in steel bending technology.

Comments